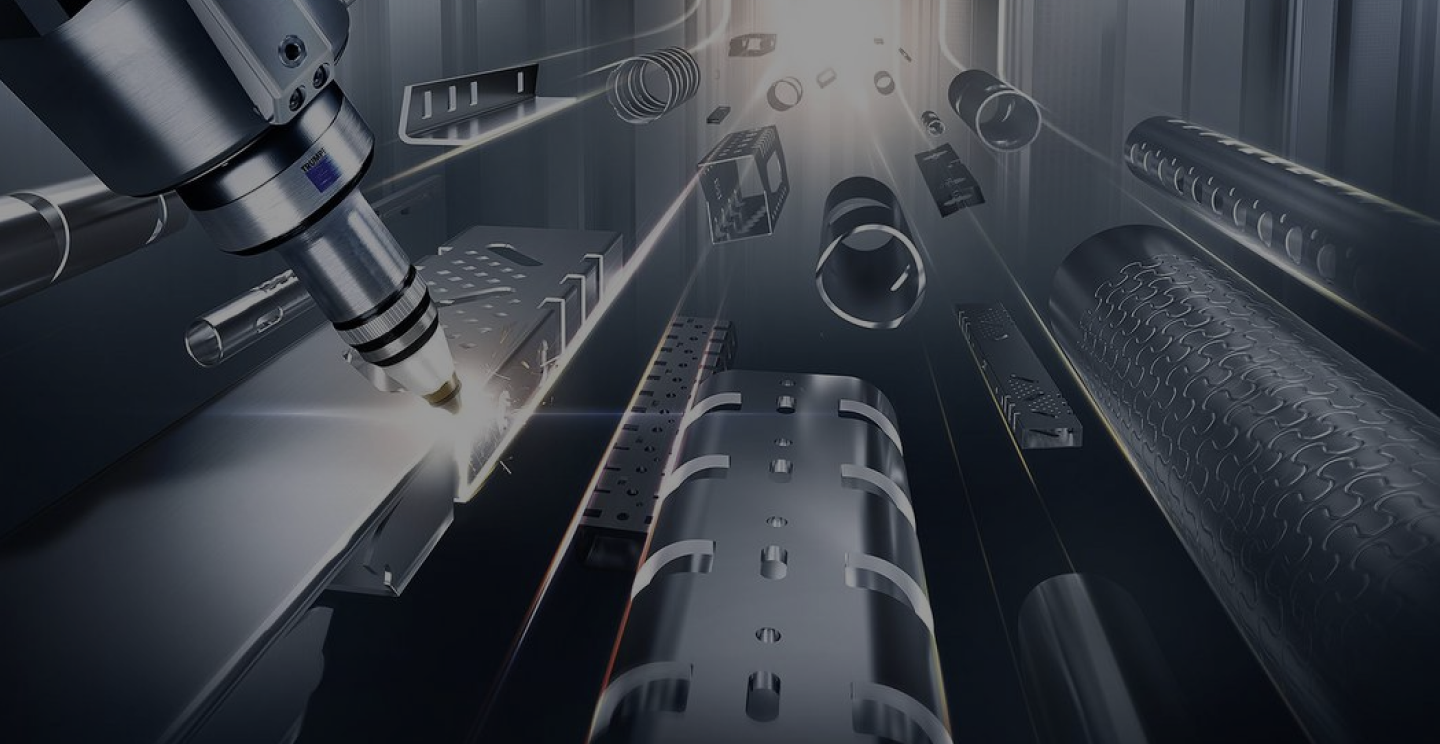

TruLaser Weld 5000

Robots, lasers, processing optics, enclosed protective housing, and positioners – TruLaser Weld 5000 is a turn-key system for automatic laser welding. You can flexibly weld deep and strong seams or nicely rounded, smooth seams using one system. FusionLine also enables you to connect components with gaps. The versatile system can be precisely tailored to meet your needs with different component positioners. The rotary module make it easier to access your components allowing you to weld faster. The shielding gas nozzle rotates continuously around the optics. The robot does not need to reorient itself. Tolerant laser welding with FusionLine, allowing you to close gaps up to 1 mm wide and to laser-weld economically without optimizing your component portfolio for laser welding. The benefit for you: The machine can process more components and your capacity increases.

Laser Welding In Sheet Metal Fabrication

Laser welding is a key development of the sheet metal process chain.

The heat input is low and the heat effctive zone is minimal at high welding speeds.

Welding connections are both visually and structurally attractive, and 5-10 times faster than conventional processes.

Warp is minimized and expensive refinishing is almost completely eliminated.

Laser welding seams are very narrow and have no heat influence zone, this minimizes warping when joining parts.

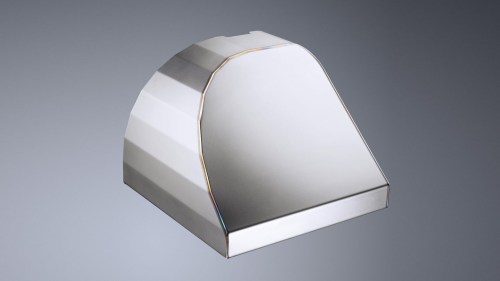

With heat conduction welding, seams can be made with high quality.

Additional refinishing, like grinding and polishing, are no longer needed.

Only laser welding makes this possible.

The laser opens up entirely new design possibilities for component construction.

Simple-to-assemble clamping systems – supported by the TruTops Cell programming system – ensure a narrow joining gap and guarantee consistency.

Valves controlled with compressed air or under pressure make automated fabrication a possibility here, too.

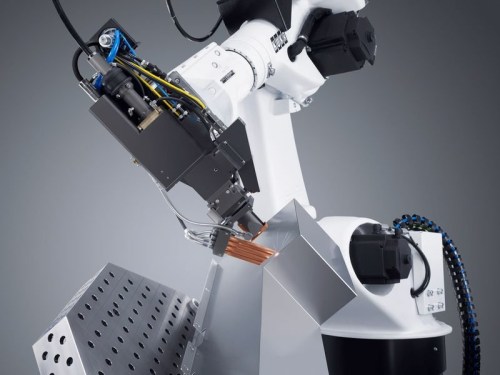

TruLaser Robot Series 5000

The TruLaser Robot is a highly integrated turnkey system from TRUMPF.

It can be integrated into a laser network very well, thus minimizing the financial investment and at the same time increasing the utilization rate of the beam source.

Its modular construction enables individually customized configuration and as such is superbly tailored to the needs of the customer.

Modular Construction = Flexibility

The great flexibility of the TruLaser Weld 5000 produces even small batches cost effectively.

We have the building blocks and you choose what suits you.

We deliver ready to go - you only have to provide the appropriate environment and preparation.

The main components are laser devices with laser light cables, robots, processing optics, safety enclosure and component positioner.

TRUMPF ensures the highest accessibility of the entire system.

A Good Grip On It

The robot has standard controls that we are expanding with operator-friendly software building blocks for laser material processing.

Robots and component positioner, the laser device and the processing optics can be controlled with the handset.

Control of the safety circuit is also integrated.

Processing Optics With Motorized Focusing & Magnetic Coupling

Thanks to the motor-driven focus-setting process, the focal position can be changed automatically. In this way, you can go back and forth between heat conduction welding and deep welding reliably.

The setting of the focal position is programmed through the control and therefore guarantees the best reproducible process results.

Applications

Deep Penetration Welding:

The laser beam welds with full penetration welding from above.

This eliminates accessibility problems even in very tight spots and small or narrow spaces.

Heat Conduction Welding:

The laser welds with heat conduction welding.

The visible seam does not have to be reworked and has reproducible seam quality.

Specifications

| Number of axes | 6 |

| Repeatability | ± .0019" (± 0.05 mm) |

| Max. Load | 550 - 2,200 lbs. (250 - 1,000 kg) |

| Max. Part Width | 78.75" (2,000 mm) |

| Max. Part Height | 27.5" (700 mm) |

| Max. Part Depth | 39.37" (1000 mm) |

| Laser Beam Source | TRUMPF TruDisk / 2,000 - 8,000 watts |