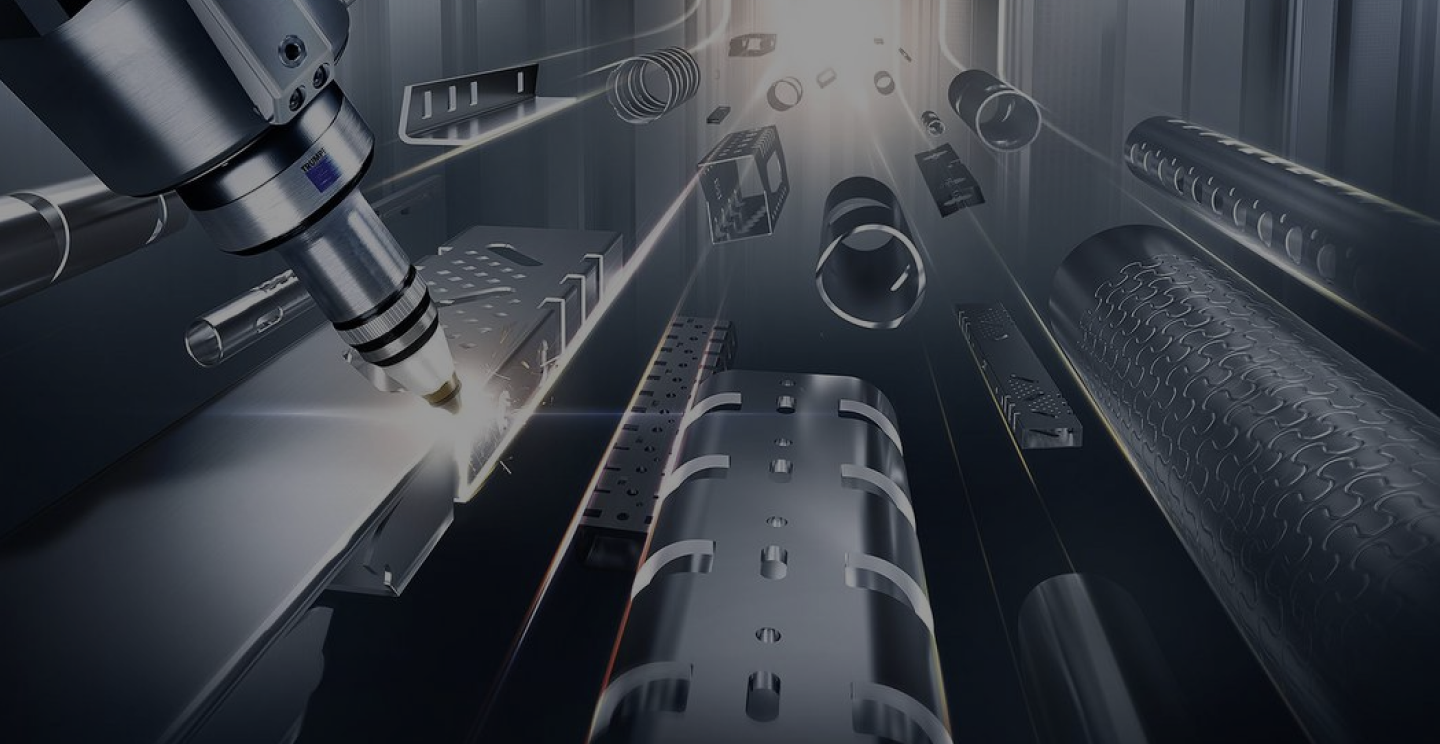

You can laser, form, punch, tap, emboss, mark, engrave and deburr with a TruMatic machine.

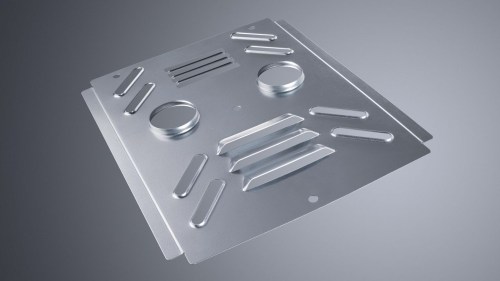

The descending die enables scratch-free punching and forming processes.

If required, the die can be lowered during positioning so the sheet does not have any contact with the die.

Advantages when both punching as well as with forming dies.

When forming downwards, there is no longer the risk of things getting caught.

Clever Parts Handling, Automatic Loading & Unloading

Removal and sorting solutions for small to large parts.

The SheetMaster Compact loads and unloads, the SortMaster Compact sorts finished parts.

Ball Tables or Brush Tables

For sensitive materials, you can use brush tables in combination with the descending die.

Parts can also be processed on the handy ball table.

.

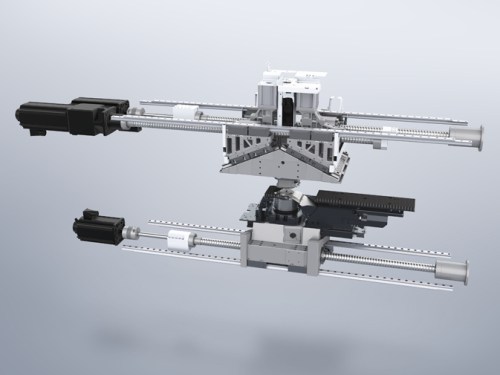

Innovative Drive, Compact Design

The Delta Drive brings more dynamic to the machine – and saves 25% of the installation area compared to a other punch machines.

Integrated Flattening

When punching sheet metals, compression and tensile stresses are placed on the workpiece which can cause sheet deformation.

The integrated flattening machine function combined with the corresponding tool eliminates surface irregularities during the punching process itself.

Smart Punch Monitoring

Before a tool change, this function checks whether the sheet has actually been punched.

This way, the machine detects when punches are broken, and can pass this information on to the operator.

Tapping Tool

Produce superior threads on the punching machine using a forming procedure.

Due to the complete processing on one machine, you can reduce your part costs.

Sorting Function

The machine automatically sorts parts up to 7" x 7".

Finished parts go through a chute into an intermediate buffer storage.

There are four different boxes under the machine.

The intermediate buffer storage moves to the correct box and adds the parts to this.

Touchpoint HMI

Easy to program punch or punch-laser parts.

Machine operation becomes as intuitive as when using a tablet or smartphone with the TRUMPF Touchpoint-HMI.

Finish parts quickly, even novices will easily learn how to work with the software.

Flexible Laser Processing

With TRUMPF's robust TruDisk solid-state laser, you can achieve excellent productivity even when cutting non-ferrous metal.

Specifications