TruPunch-TruMatic 1000 fiber

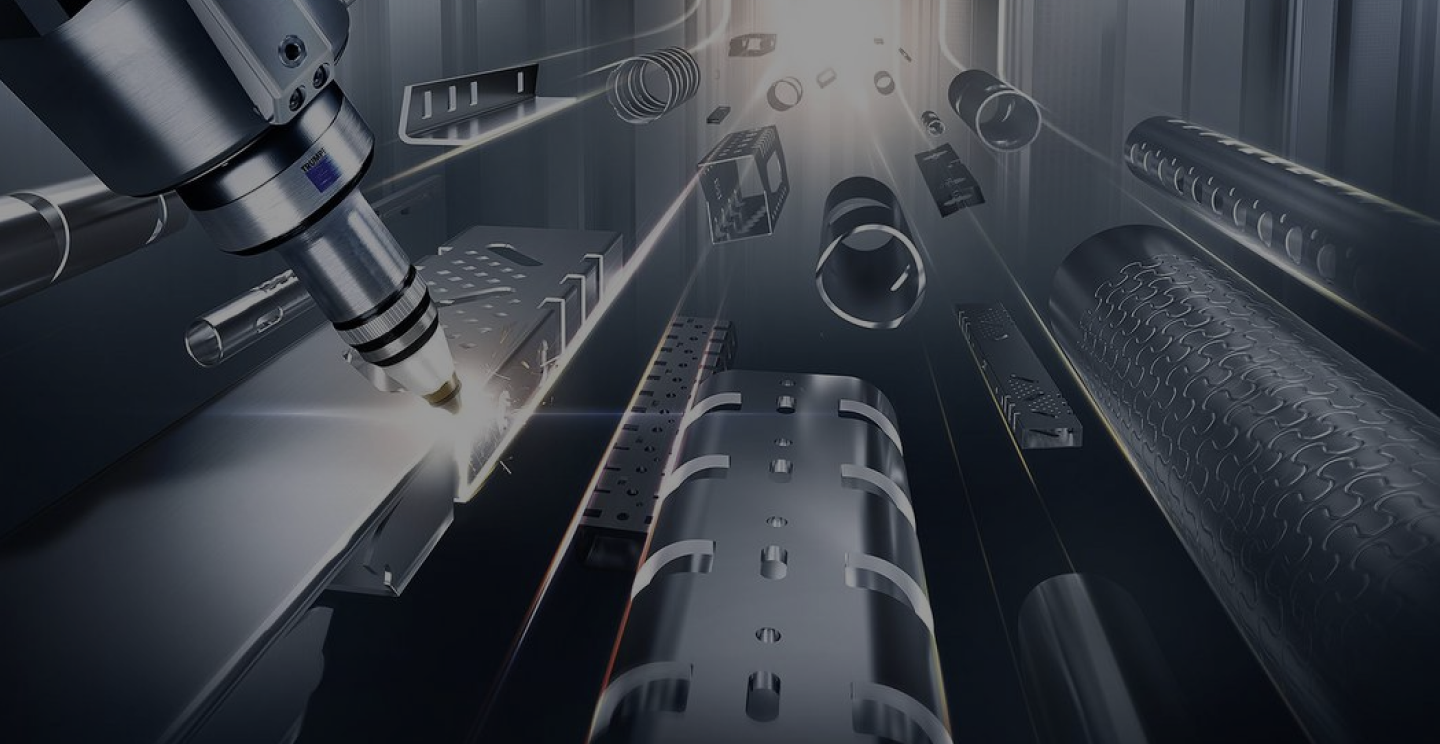

The TruMatic 1000 fiber is a laser machine that punches holes, bends flanges, and forms threads. It is the world's most compact punch laser machine.

The TruMatic 1000 fiber is available as a complete solution, but can also be upgraded to a punch laser machine gradually, starting from the TruPunch 1000 entry-level punching machine. Discover the clever solutions for part sorting and automated operation.

TruPunch-TruMatic 1000

The TruPunch 1000: a machine that grows with you

The TruMatic 1000 fiber offers an especially cost-effective combination of the advantages of punch and laser processing.

It flexibly cuts contours with the laser, punches, forms and taps threads – with clever automation in confined spaces.

Revolutionary in its modular design, the TruMatic 1000 fiber is a punch/laser machine featuring an electric punch and solid-state laser.

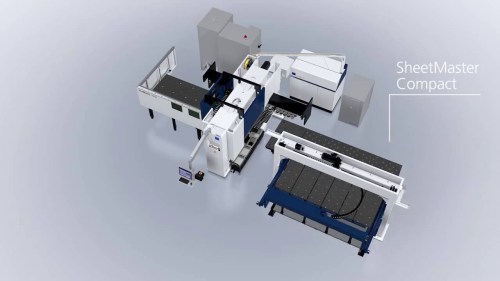

Economical and compact, the machine is automation-friendly and designed to grow with your needs – from a punching machine to a fully automated punch/laser system.

The TruMatic 1000 fiber is built with increased machine dynamics, productivity and process stability in mind.

With the integration of SheetMaster Compact, an innovative material handling solution, further production improvements are realized.

Benefits

Space-saving machine design

Clever unloading solutions

Compact automation

Innovative Drive

The patented Delta Drive makes it unnecessary to move the sheet and support table along the Y axis.

For the first time, it allows the punching head to "fly" over the sheet, i.e. to and fro – at high speed.

The Delta Drive enables the TruMatic 1000 fiber to have low space requirements even though it is automated.

The Delta Drive decouples punch and die and, in this way, enables new punching applications, such as the removal of very small, laser-cut parts.

Flexible Punch Laser Processing

The TruDisk 3001 solid-state laser allows the TruMatic 1000 fiber to flexibly cut any contour of your choice.

Besides pure punching, it can also form threads, apply extrusions and bend flanges.

The machine allows to produce a large part spectrum completely on one machine.

NEW! SortMaster Compact Automation Option

The SortMaster Compact removes, sorts and stacks individual parts up to 24 inches x 16 inches and up to 33 lbs.

Requiring almost no additional floorspace, the SortMaster Compact deposits the parts to an easily accessible location in front of the machine.

The individually programmable suction cups are of varying diameters to handle a variety of part configurations and contain sensors to ensure reliable operation.

When removing small parts, the delta drive enables the punching or laser head to move away while the die supports the part during removal.

You can use the SheetMaster Compact to load sheets and blanks up to a medium format size and unload microjoint and scrap skeleton sheets.

This is largely done parallel to production thanks to its optimized loading and unloading cycles.

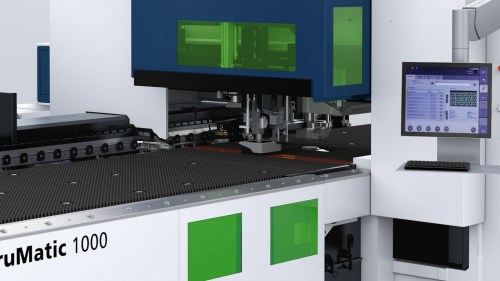

Simple Operation

With the beam guard in a space-neutral position, optimum safety is ensured and, at the same time, good access to the machine.

The containers for finished parts and scrap are very easily accessible.

The operating logic and menu navigation are based on the requirements of the operator.

Operation takes place intuitively on a touch screen on the operating panel.

Mobile operation of the machine using the MobileControl app.

EasyUse allows you to easily set up tools.

Specifications

| Medium Format | Large Format | |

| Working area, (Punch operation) | 50" x 100" | 60" x 120" |

| Working area, (Combined operation) | 50" x 80" | 60" x 100" |

| Max. sheet thickness | .250" | .250" |

| Max. punching force | 18 tons | 18 tons |

| Laser / output power | TruDisk 3001 (3 kW) | TruDisk 3001 3kW |

| Speed, Simultaneous (X and Y) | 3,937 ipm | 3,937 ipm |

| Max. stroke rate (punching) (E = .039") | 600 hpm | 600 hpm |

| Max. stroke rate (marking) | 1000 hpm | 100 hpm |

| Max. part size, chute | 7" x 7" | 7" x 7" |

| * Large part flap size (X x Y) | 16" x 48* | 16" x 48" |

| * Reliable ejection of parts measuring max. 16 x 48 inches. |