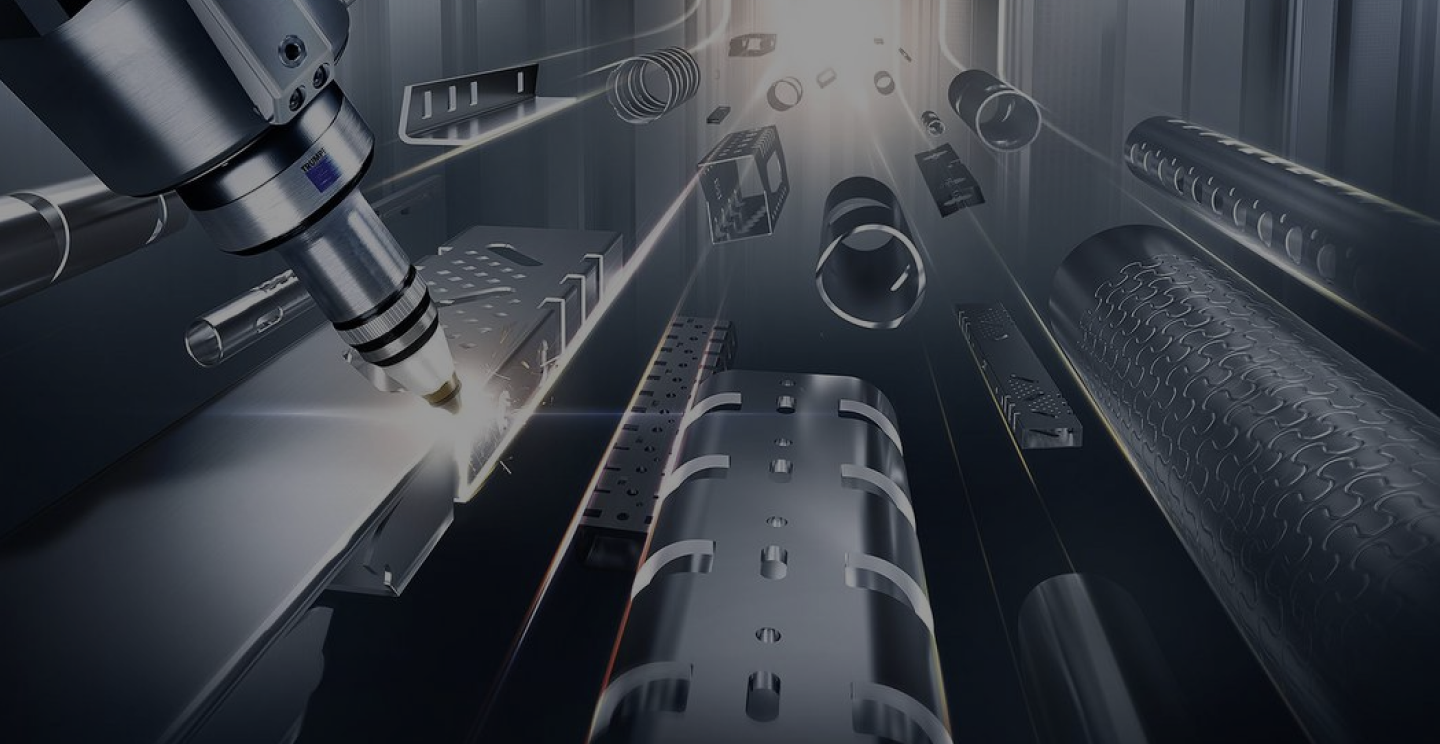

TruLaser Center 7030 Fiber

This fully automatic machine guarantees reliable part handling thanks to in-built intelligence with automation solutions such as SmartGate, SmartLift and SortMaster Speed. This eliminates the possibility of workpieces tipping over or tilting and the need to use microjoints. Full-service machine for your laser production

The TruLaser Center 7030 integrates all laser cutting processes into a single machine for the first time. The advantage for you: Your throughput time and processing costs will be drastically reduced. As a result, you get the optimal profitability out of your laser machining process.

The TruLaser Center 7030

Anyone who wants to manufacture using laser cutting in an economical way, needs a machine in which all steps are interlinked. This is where the TruLaser Center 7030 scores with the close interaction between integrated intelligence and new automation solutions.

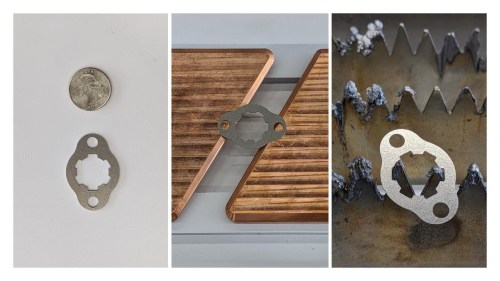

TRUMPF has fundamentally questioned the entire process of laser processing. The result? A groundbreaking machine concept combining productivity and process reliability. Unlike conventional 2D laser machines, the TruLaser Center 7030 moves the sheet as well as the cutting head. With the additional axis on the cutting head, this machine achieves peak values in terms of cutting dynamics. The result of this are overlapping axis movements that make your machine extremely powerful. Equipped with a laser power of 6000 W, this enables you to cut through sheets with a thickness of up to .500" in a highly dynamic manner.

Intelligent Automation

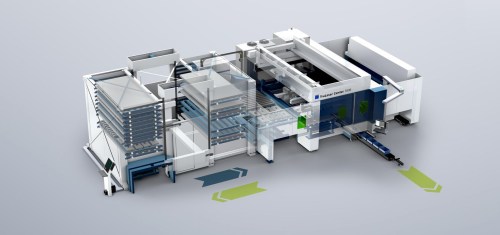

This fully automatic machine guarantees reliable part handling thanks to in-built intelligence with automation solutions such as SmartGate, SmartLift and SortMaster Speed. This eliminates the possibility of workpieces tipping over or tilting and the need to use microjoints. The TruLaser Center not only cuts in high quality and fast, it also takes care of many sorting steps completely by itself. Connected to a storage system, it tackles many tasks at the same time. For example, finished parts are stored and simultaneously, the machine is loaded with new raw material. Also at the same time, you can remove small parts, and you can approve new programs parallel to production. Thus, the operator doesn’t have to stay close to the machine all the time.

Producing Around The Clock

Connect the TruLaser Center 7030 to your store and profit from a higher machine utilization rate because of the optimized material flow and lower material access time. The machine takes care of bothersome and monotonous work steps for you around the clock – this saves manpower and relieves the strain on employees.

Programming An Order

At the press of a button, the TruTops Boost programming system performs a fully automatic calculation for a comprehensive proposal for the cutting, removal, sorting, and depositing of your parts.

Loading Raw Sheets

The loading cart can be loaded parallel to production. The LoadMaster Center places the raw sheet on the brush table in the clamping unit. High-performance peeling techniques separate the sheet reliably from the stack.

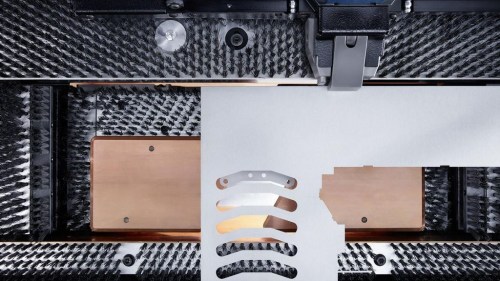

Cutting Parts

The clamping unit moves the sheet in the Y direction, the cutting unit processes it in the X direction and also in the Y direction using a highly dynamic additional axis. The SmartGate supports the cutting process.

Removing Parts & Scrap

The intelligent SmartGate removes slugs, scrap, and small parts reliably. The sorting flap separates finished cut parts from scrap. Finished parts are sorted into eight containers. Scrap and slugs fall into a slag cart.

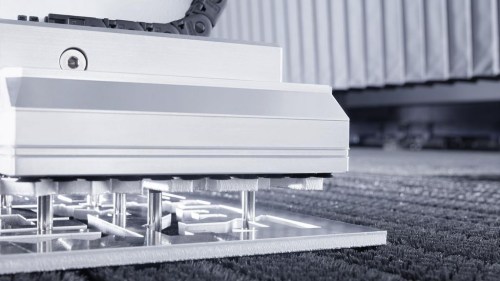

Unloading Parts

The SmartLift uses its pins to push the parts out of the scrap skeleton. The finely structured suction plates of the SortMaster Speed remove the cut parts, and sort and stack them on the parts deposit. The suction plates and pins prevent any tilting of the parts.

Specifications

| Working Range | |

| X axis | 120" |

| Y axis | 60" |

| Y2 axis | 4.7" |

| Maximum Sheet Weight | 1021 lbs. |

| Maximum Workpiece Weight | 265 lbs. |

| Speeds | |

| Simultaneous (X and Y) | 462.6 ipm |

| Accuracy | |

| Smallest Programmable Increment | 0.00004" |

| Positioning accuracy (Pa) | 0.002" |

| Repeatability (Ps) | 0.0012" |

| TruDisk 6001 TRUMPF Solid State Laser | 6,000 Watts |

| TruDisk 12001 TRUMPF Solid State Laser | 12,000 Watts |

| Maximum Sheet Thickness | |

| Mild steel (O2) | 0.500" |

| Stainless steel (N2) | 0.500" |

| Aluminum (N2) | 0.250" |

| Copper (O2) | 0.250" |

| Copper (N2) | 0.250" |

| Brass (N2) | 0.250" |

| Electrical Consumption Values (incl. chiller) | 7 - 36 kW |

| Dimensions & Weight | |

| Length | 33.25' |

| Width (carts retracted) | 21' |

| Width (carts extended) | 35.17' |

| Height | 10' |

| Weight | 50,000 lbs. |