TruLaser 3000 Series Fiber Lasers

TruLaser 3000 fiber Series

The machines of the TruLaser Series 3000 are true all-rounders in laser cutting and are extremely flexible and reliable. The TruLaser 3000 fiber series features both high-speed cutting and processing flexibility, resulting in maximum profitability. The fiber-delivered TruDisk laser excels not only at thin sheet cutting, but also in steel up to 1" thick with peak performance, cut quality and low operating cost. Stainless steel, aluminum and copper can also be cut with speed and quality, giving you a full range of capabilities. Switching between materials is fast and easy, thanks to the automatic nozzle changer and the single cutting head. To further expand capabilities, the TruLaser 3000 Series fiber may be optionally equipped with RotoLas for tube processing.

BrightLine fiber

BrightLine fiber turns the solid-state laser into a universal tool: The function provides you with high-quality cutting results over the entire range of sheet thicknesses. Furthermore, all of the advantages of the solid-state laser are retained, in particular the high speeds, during thin sheet processing.

Collision Protection

Collision protection for your cutting head guarantees the highest process reliability. You benefit from shorter non-productive times due to increased machine availability. In the event of collisions, damage to the cutting head is avoided.

Online Condition Check - Protective Glass

Clean protective glass ensures high cut quality for the long term. A sensor permanently monitors the condition of the protective glass so that you know when it must be changed. Cleaning and replacement are only performed when required, saving costs.

Condition Guide

One glance is enough: Due to the new Condition Guide function, you are always informed about the condition of your machine. A traffic light system shows the status of important elements which influence the cutting capability of the machine. Condition Guide will give you recommendations for action as required. Process diagrams facilitate forecasting as to when action may need to be taken. Maintenance work can therefore be planned efficiently.

Smart Collision Prevention

Smart collision prevention reduces the risk of collisions during laser cutting to a minimum. From the part contours, the process detects the parts which are at risk of tilting. It creates an optimized job processing strategy: The laser skillfully navigates around parts at risk of tilting. They are only cut free when there is no longer the risk of collision. This means you do not need to use microjoints, saving costly rework.

DetectLine

A camera system precisely determines the position of inserted sheets and enables the rework of parts which have already been cut with absolute precision. DetectLine also automatically measures a cut focusing comb and sets the focal position.

Highspeed

Quick and economic – without compromising on quality: With Highspeed, you can set new records with the solid-state laser when it comes to cutting with nitrogen. As a result, you can almost double your sheet throughput for medium and thick mild steel and stainless steel sheets – the same goes for the feed rate. A special nozzle design also reduces your cutting gas consumption by up to 40%, and even prevents burr formation on contours with sharp edges.

Highspeed Eco

Extremely quick, extremely economical: With this Highspeed process, you can reduce your cutting gas consumption for cutting with nitrogen by up to 60%. This is enabled by a patented nozzle design. At the same time, you can almost double your sheet throughput for medium and thick mild steel and stainless steel sheets, and increase the feed rate by up to 100%. Quality does not suffer as a result. Highspeed Eco even prevents burr formation on contours with sharp edges. The process also harnesses new sheet thicknesses for processing with nitrogen.

Mobile Control app

With the MobileControl app, you can operate and monitor your machines easily and with flexibility as the app transmits the interface of the standard control panel onto the touch screen of your tablet PC. The app enables you to call up different machine information at different places in the working environment of the machine, such as the clearing area, or to change the program.

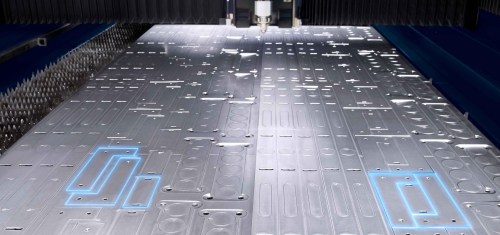

Drop&Cut

With Drop&Cut, remainder sheet is utilized more easily, intuitively, and efficiently. A camera ensures the live image of the machine interior appears directly on your user interface. You can position any number of part geometries on the remainder sheet. This saves time during the post-production of individual parts. Time-consuming process steps such as aligning the sheet, sheet position measurement or zero point displacement is not needed.

Nanojoints

TRUMPF NanoJoints Process-reliable laser cutting.

In comparison to microjoints, TRUMPF nanojoints only connect the component to the scrap skeleton via a small stop point at the bottom end of the kerf.

This leads to process-reliable machining of the sheets as it prevents the components from tilting.

Damage to contours is only minimal and it is much easier to release your parts from the scrap skeleton.

Your nesting can be tighter, you utilize your resources more efficiently, and benefit from higher productivity.

Tube Cutting Unit

With the optional tube cutting unit expand the range of potential parts with the addition of tube profiles. Offers a high flexibility in tube geometry. No setup work required on machine cutting unit.

Higher Laser Power on Demand

With TRUMPF's Power by the Hour option, you can independently choose when you need to use more laser power. This unique program provides the ability to switch laser power on the TruLaser 3000 series from the optional 6kW to 10kW during production, without needing to call TRUMPF. With this added flexibility, you are able to expand the range of materials and material thicknesses you can cut on your laser, boosting overall productivity with higher throughput on demand and greater material capacity when you need it. When cutting at a higher laser power, you will only be invoiced for what you use.

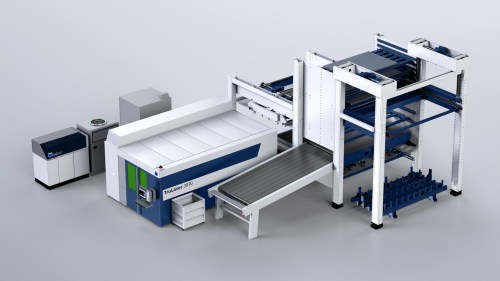

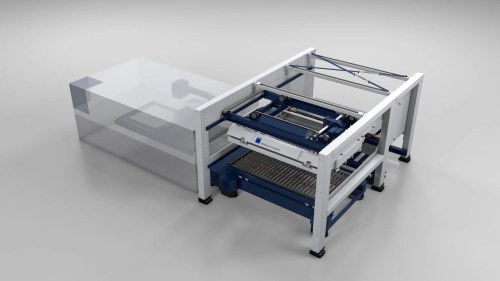

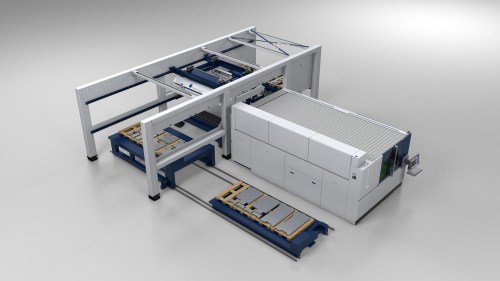

Automation: LiftMaster Compact

The LiftMaster Compact is the fastest and most compact loading and unloading unit in the TRUMPF portfolio. The dynamic and variable automation solution is particularly attractive for fast sheet processing times, regardless of whether with or without storage connection. It requires little space and saves time and money with its short cycle time of 90 seconds. For a complete loading and unloading cycle, including pallet change, the LiftMaster Compact requires just 90 seconds. With the synchronous loader, the LiftMaster Compact can load and unload workpieces simultaneously.

Automation: A Modular Approach

Expand your LiftMaster Compact over time into a complete processing cell with a TruStore Material Tower with TRUMPF's PartMaster sorting station.

Specifications

| Working Range | TruLaser 3030 fiber | TruLaser 3040 fiber | TruLaser 3060 fiber | TruLaser 3080 fiber |

| X Axis | 3,000 mm / 118.10" | 4,000 mm / 157.50" | 6,000 mm / 236" | 8,000 / 314.96" |

| Y Axis | 1,500 mm / 59" | 2,000 mm / 78.75" | 2,500 mm / 98.42" | 2,500 mm / 98.42" |

| Z Axis | 114.5 mm / 4.5" | 114.5 mm / 4.5" | 114.5 mm / 4.5" | 114.5 mm / 4.5" |

| Workpiece Maximum Weight | 1,984 lbs. | 3,748 lbs. | 6,614 lbs. | 10,383 lbs. |

| *17,300 lbs. | ||||

| Max Speed, (Simultaneous) | 5,512 ipm | 5,512 ipm | 5,512 ipm | 5,512 ipm |

| Accuracy | .002" | .002" | .002" | .002" |

| Repeatability | .0012" | .0012" | .0012" | .0012" |

* With Heavy Duty Pallet Changer

TRUMPF Solid-State Laser Options

| TRUMPF TruDisk 4KW | TRUMPF TruDisk 6KW | TRUMPF TruDisk 8KW | TRUMPF TruDisk 10KW | TRUMPF TruDisk 12KW | |

| Max Thickness Mild Steel | 1.00" | 1.00" | 1.00" | 1.25" | 1.25" |

| Max Thickness Stainless Steel | 0.75" | 1.00" | 1.18" | 1.50" | 2.00" |

| Max Thickness Aluminum | 0.75" | 1.00" | 1.00" | 1.18" | 1.18" |

| Max Thickness Copper | 0.31" | 0.40" | 0.40" | .50" | .50" |

| Max Thickness Brass | 0.31" | 0.40" | 0.40" | .50" | .50" |