SUNRISE Hydraulic Horizontal Benders

Sunrise Horizontal Benders

The hydraulic bending machine from SUNRISE offers a high quality and reliable hydraulic metal working machine.

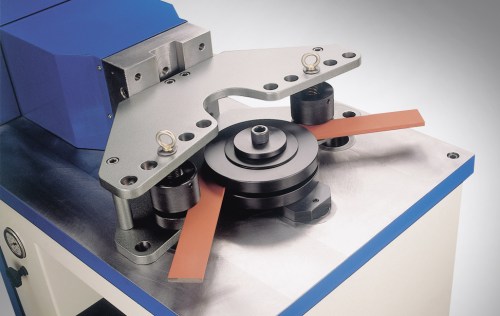

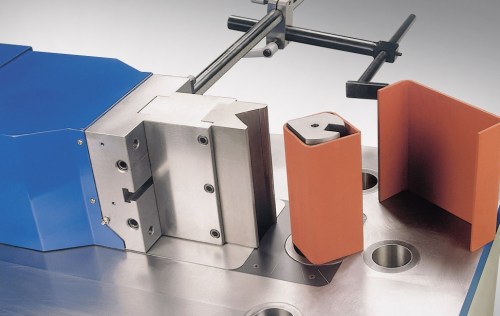

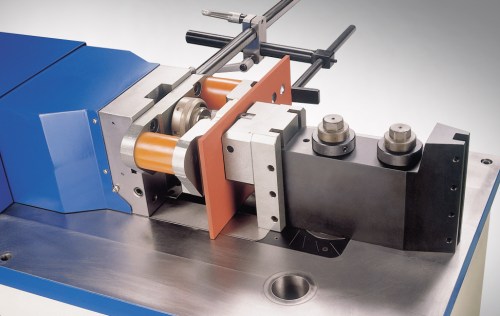

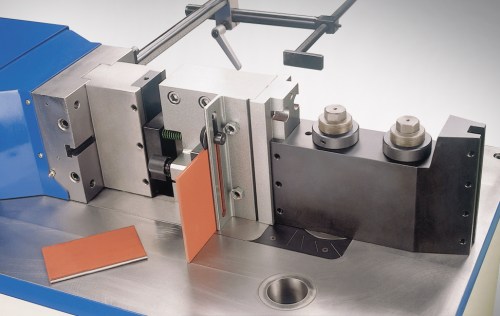

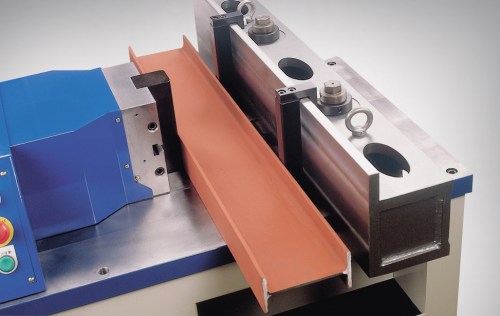

A wide range of tooling is available for different bending operations. Custom tooling is also available.

SUNRISE horizontal bending machines feature:

Excellent repeatability of stroke with an accuracy of +- 0.004″ with Digital Linear Encoder and Proximity Sensors.

Programmable touch screen controller – Standard.

Name brand electric and hydraulic components ensure machine reliability.

CNC machined one-piece solid table design.

A wide range of standard and custom tooling is available.

Manual back gauge is included for accurate positioning.

Both HBM models feature a programmable touch-screen controller with 50 program memory standard.

Trilogy Machinery offers 100% factory authorized service and support as well as a full stock of spare parts and accessories from their Baltimore location.

Sunrise CNC

Specifications

| Model | Capacity | Force | Forward Speed | Stroke | Working Height | Motor HP | Weight |

| HBM-45 – Manual | 8″ x 1/2″ | 45 Tons | 1.5″/ Sec | 10″ | 37″ | 5 | 2,275 |

| HBM-45 | 8″ x 1/2″ | 45 Tons | 1.5″/ Sec | 10″ | 37″ | 5 | 2,275 |

| HBM-82 | 12" x 1/2" | 82 Tons | 1.5″/ Sec | 14″ | 37.5″ | 7.5 | 4,575 |